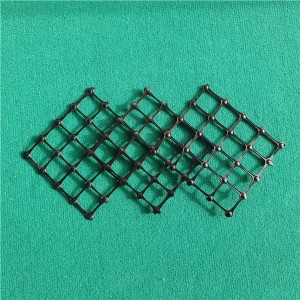

Isici esiyinhloko sokucindezeleka se-geogrid yensimbi eyinhlanganisela yensimbi iyinsimbi yensimbi, enokonakala okuphansi kakhulu.

1. Amandla aqinile we-geogrid eyinhlanganisela yepulasitiki yensimbi athwalwa izintambo zensimbi eziqine kakhulu ezilukwe ku-warp ne-weft, ezikhiqiza imodulus eqinile ephezulu kakhulu ngaphansi komthamo ophansi wobunzima.Izimbambo ze-longitudinal kanye ne-transverse ziyasebenzisana ukuze zisebenzise ngokugcwele umthelela wokuhlangana we-geogrid emhlabathini.

2. Izintambo zensimbi zezimbambo eziqondile nezivundlile zepulasitiki yensimbi eyinhlanganisela ye-geogrid zilukwa zibe iwebhu nge-warp ne-weft, futhi ungqimba olusonga lwangaphandle lwakhiwa ngesikhathi esisodwa.Izintambo zensimbi kanye nesendlalelo sokugoqa sangaphandle singaxhumanisa, nge-elongation ephukile ephansi (hhayi ngaphezu kuka-3%).Isici esiyinhloko sokucindezeleka se-geogrid yensimbi eyinhlanganisela yensimbi ucingo lwensimbi, olunokwehla okuphansi kakhulu.

3. Ngokwelashwa kwendawo yepulasitiki phakathi nenqubo yokukhiqiza, amaphethini amaholoholo ayacindezelwa ukuze kuthuthukiswe ukuhwalala kwendawo yegridi futhi kuthuthukiswe i-coefficient yokungqubuzana phakathi kwe-steel plastic composite geogrid nomhlabathi.

4. Ububanzi be-geogrid eyinhlanganisela yepulasitiki yensimbi bungafinyelela ku-6m, bufinyelele umphumela wokuqinisa ophumelelayo nowongayo.

5. I-polyethylene enobukhulu obuphezulu esetshenziswa ku-geogrid eyinhlanganisela yepulasitiki yensimbi ingaqinisekisa ukuthi ngeke idliwe yi-asidi, i-alkali, isixazululo sikasawoti, noma uwoyela ezingeni lokushisa elivamile;Ayikho ngaphansi kokuncibilika kwamanzi noma ukuhlasela kwe-microbial.Ngesikhathi esifanayo, izakhiwo ze-polymer ze-polyethylene zanele ukumelana nokuguga okubangelwa imisebe yangaphandle.Ngemuva kokuthi igridi igcizelelwe, izimbambo eziqondile nezivundlile zibambisana ukuvimbela ama-node ukuthi angaqhekeki noma alimale.Kodwa-ke, kumaphrojekthi wangempela, ngemva kokuhlanganiswa kwe-filler, ayikho ngaphansi kokukhanya kwe-ultraviolet nokuguguleka kwe-oxygen, ngakho-ke ingakwazi ukuhlangabezana ngokugcwele nezidingo zokwakha ubunjiniyela obungapheli.

Isikhathi sokuthumela: Apr-21-2023